As all of our frames are assembled on site, a lot of our customers are keen to take a peek in the workshop to see how and where their work is framed. With heavy-duty machinery and huge sheets of glass around - not to mention other customers' valuable artworks - I can't let people roam around for obvious health and safety reasons. So I thought a post about how picture frames are made would be enlightening for those interested.

There are several stages to each job, requiring different pieces of equipment along the way. As you can imagine, one of the most important elements is the mitre joint - two 45° cuts making a 90° corner - of the moulding (that’s the name of the outer-edge of the frame). All our wooden mouldings are cut to size on site using the guillotine.

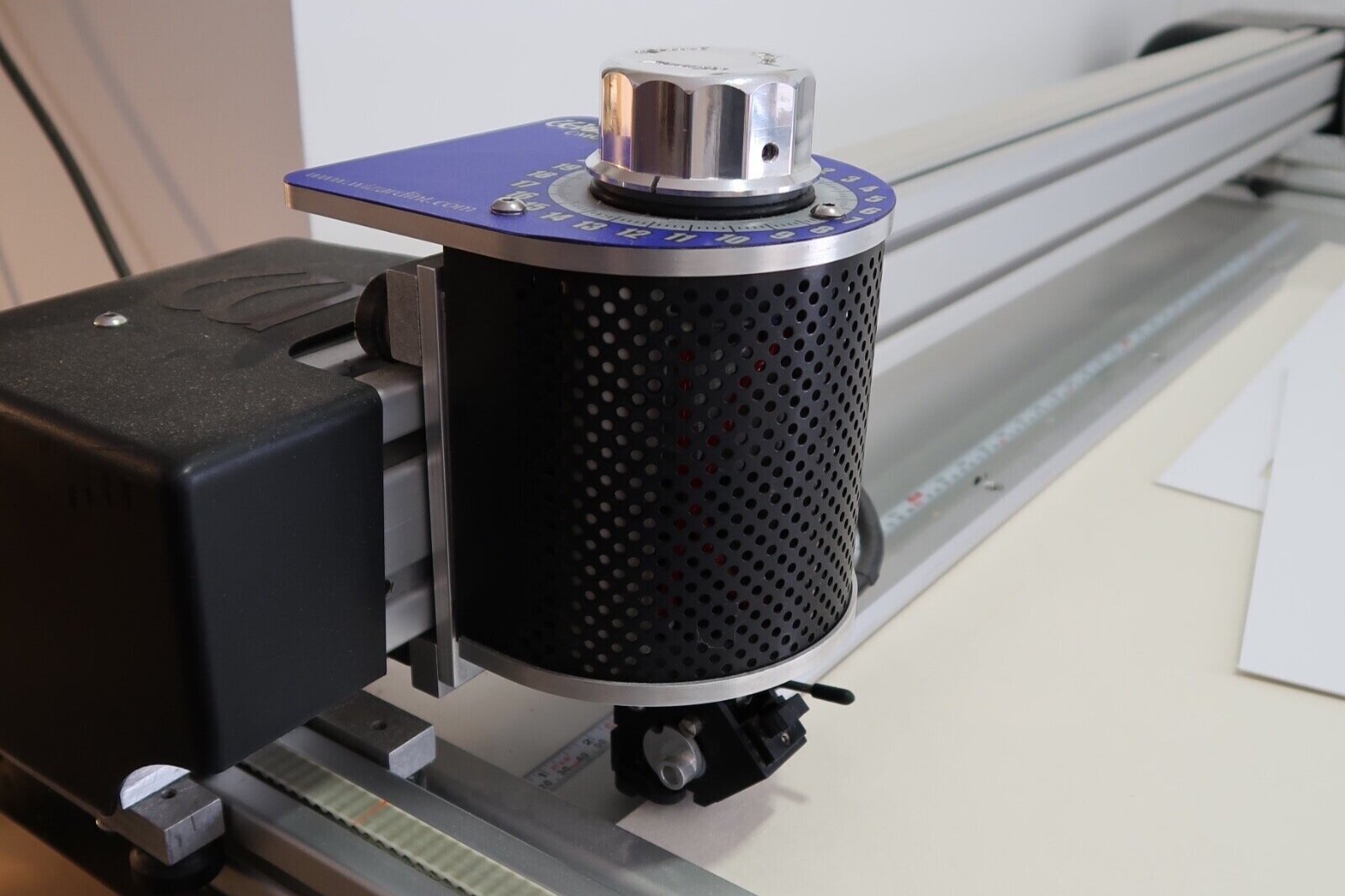

Once the moulding is cut we assemble it using glue, which helps provide additional strength, and then we join the corners with the underpinner. This is a specialist piece of machinery specifically designed for this sole purpose. A steel wedge is fired into the underside of the moulding to hold the corners tight and strong.

We also have a vertical precision cutter which is used to cut the glass, mountboard and backing board to the exact size required for each job.

The mountboard (the cardboard or, occasionally, fabric which sits between the moulding and the picture itself) is then laid on the computerised mount cutter for any apertures to be neatly and cleanly cut to the size and shape required. Having the computerised machine, rather than doing it by hand, means that there is really no limit to the shapes that we can cut out; standard rectangles, ovals and even more intricate shapes with a combination of curved and straight edges, such as those used in the Linda and Leo piece, are all possible.

The final cleaning and assembly process is completed by hand, which we carry out on the large workbench in the centre of the workshop. We have an oversized bench so that we can accommodate multiple jobs that are in progress at any one time and also large pieces of artwork.

Having everything on site also means we can carry all the basic materials and a selection of mouldings and mountboards in stock, to help with the occasional fast turnaround job.